Gearheads and do-it-yourselfers have had it happen at least once. You go to tighten down that one bolt and just when you think it should stop spinning you lose all resistance. No one likes working with a stripped bolt. Believe it or not, there are a few ways to tackle this issue. This will be a guide on how to repair stripped threads in aluminum.

Try a longer bolt

Over time bolts and threads sometimes lose their strength. Due to friction or corrosion, the threads can deteriorate. Having these weak threads can prevent you from being able to tighten down a bolt. The first option is looking at the bolt hole. If you have some extra distance that the bolt doesn’t cover you may be able to use a longer bolt. If there are some decent threads that your longer bolt can reach you may be able to tighten it down.

Use a thicker bolt

If most of the threads have been a victim of damage you may be able to increase the size of the hole. As long as there is enough room on the outside you may be able to drill out a larger hole. This will allow you to rethread the hole and give you the ability to use a larger bolt.

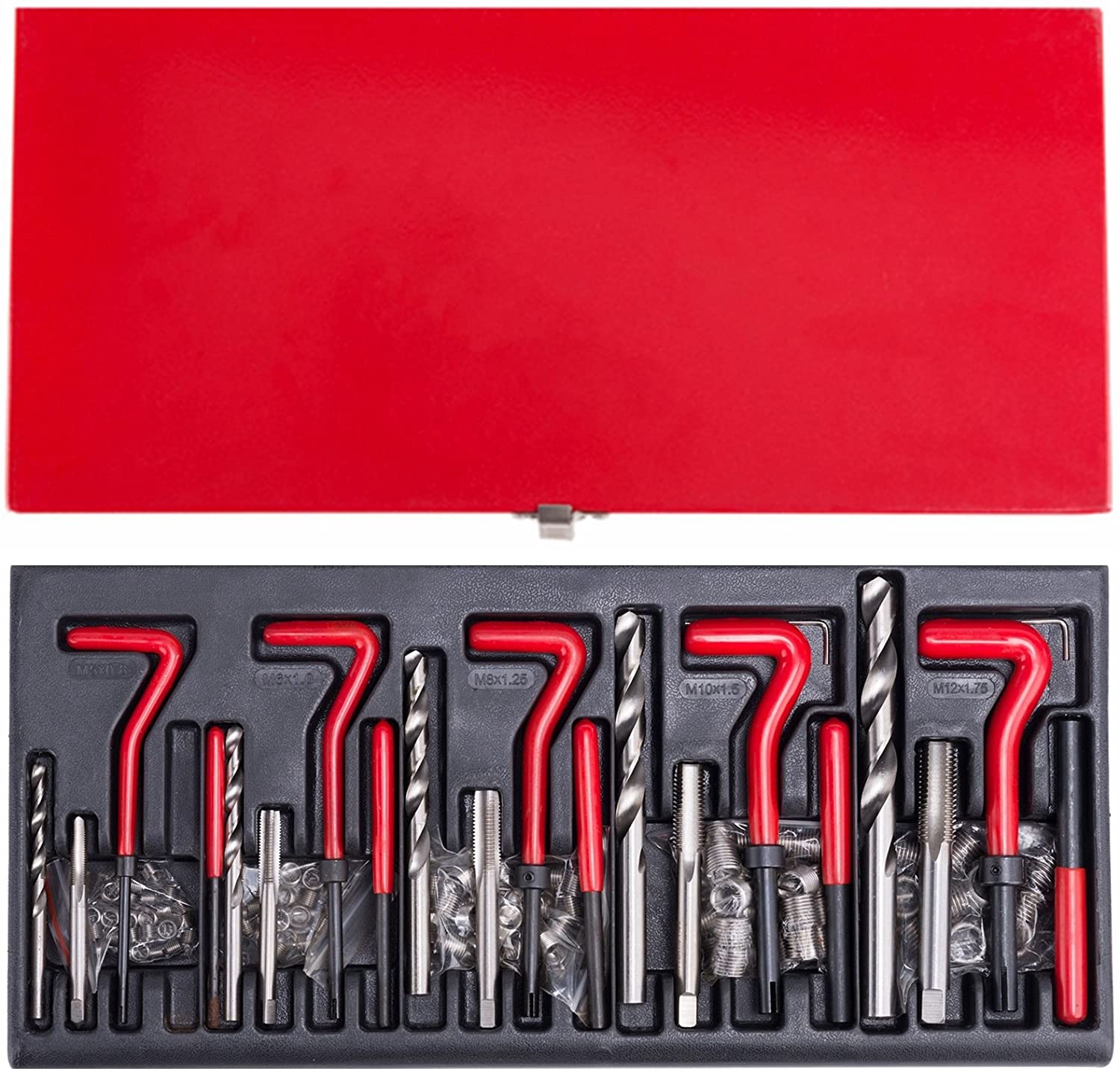

Insert a helicoil

If neither of the options above are doing it for you can use a Helicoil. A Helicoil is a coil wired thread insert. The coil replaces the original threads. Essentially you drill out the hole with the correct bit size. You can then tap the hole and insert the coil. After the coil is inserted you then bust off the tang. Sometimes you can use Loctite to secure the coil. Allow it to dry for a while then you can screw in your bolt.

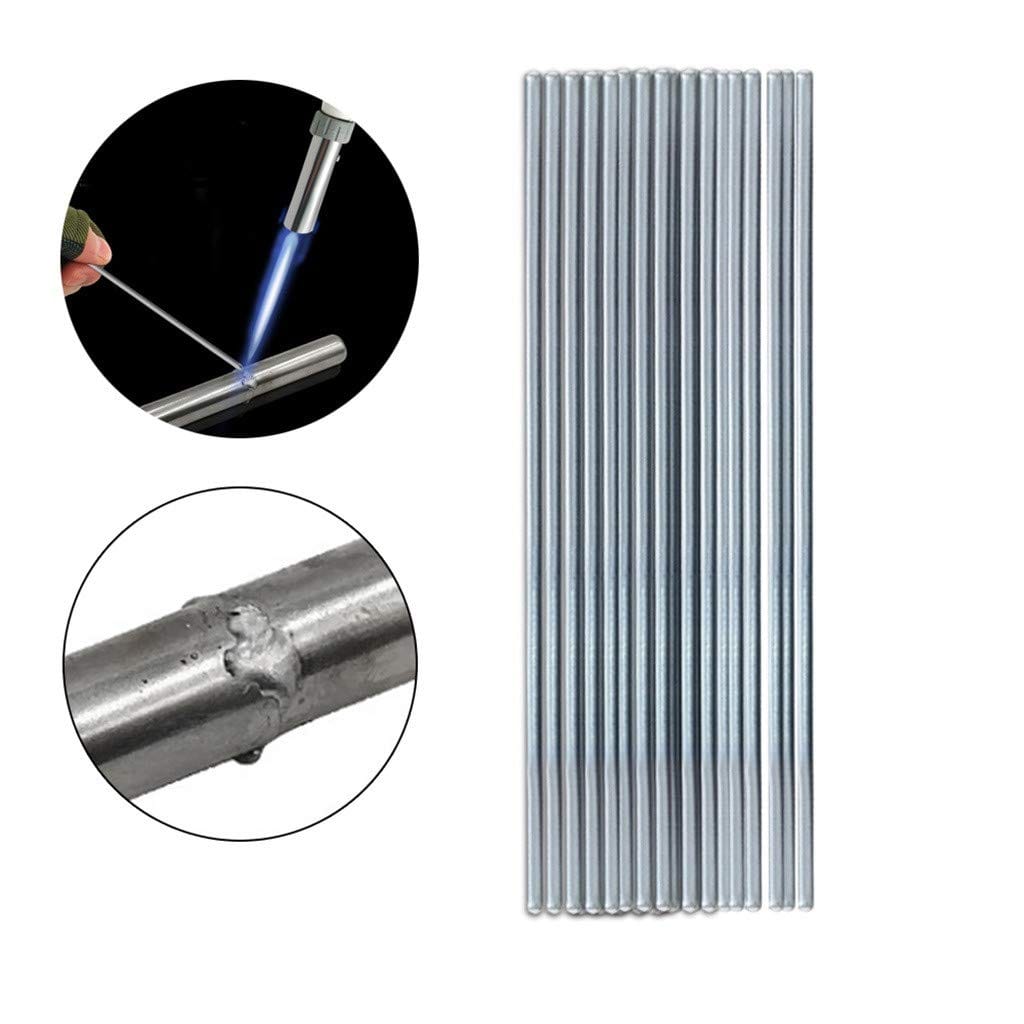

Try an aluminum braising rod

If you are able to you can heat up the area and use an aluminum braising rod. The process is almost like soldering where the aluminum melts then cools to create a solid surface. You have to heat up the surface to a temperature where the aluminum rods will melt. If there are heat-sensitive objects nearby you may not be able to use this option. If you’re fine with heating up the area you can fill then retap the hole. This will help you repair stripped threads in aluminum

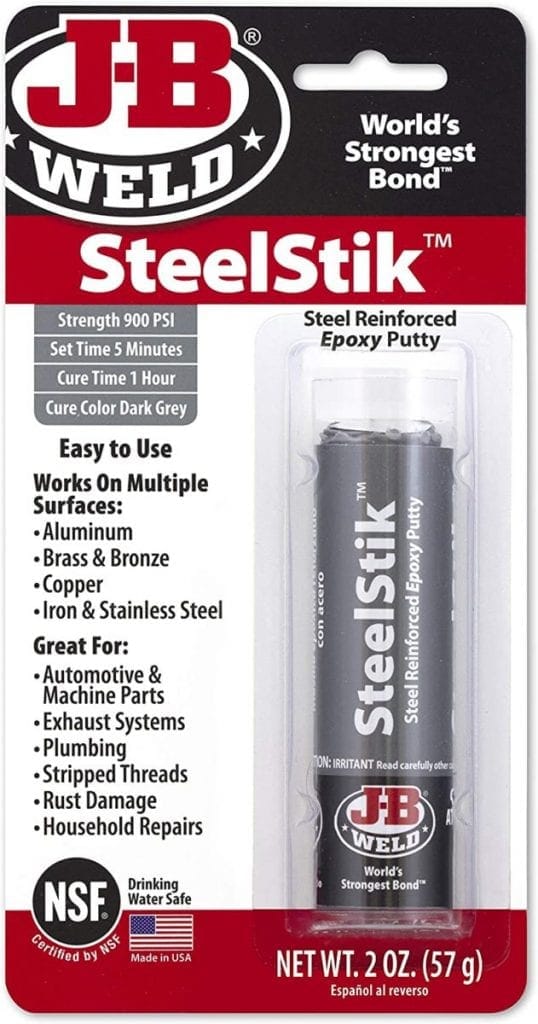

Use JB Weld

If you’re looking for something a little quicker or more permanent you might want to try JB Weld. JB Weld is usually a 2 step epoxy that can be used to join things together permanently. Alternatively, you can use the stripped thread repair epoxy to fill the hole and tap it afterward. If you are not worried about being able to remove the bolt later on you can put the JB Weld on the bolt and tighten it down. In most cases it should not move ever again.

Try strands of copper wire

Copper wire, which can usually be purchased at your local hardware store, is also a good option. You can separate the strands, fold them over, and place them inside the bolt hole. After you repeat this a few times you should be able to tighten down the bolt. The copper will bite into the threads which will keep your bolt snuggly in place.

Use aluminum foil

Just like the the copper wire above aluminum foil can be used in the same fashion. Tear a few pieces of aluminum foil off and fold them over. Place them down in the bolt hole and after a few twists of the bolt it should start to become snug.

Pour some Loctite epoxy

Certain types of Loctite are made not only for keeping a bolt secured but they also create epoxy to help repair threads. Depending on the application there are multiple levels of Loctite available. Ranging from low to high strength you can use the epoxy to permanently secure the bolt to the hole.

Use a welder

Well if you’ve made it this far and nothing else worked you might to to try your hand at welding. If you have experience you should be able to fill the hole and retap the threads. From there it should be as good as new.

In conclusion

Not all hope is lost! If you tighten your bolt two turns past stripped you might be able to repair the hole and get everything back up and running! If you had wondered how to repair stripped threads in an aluminum head one of the options above might do the trick. Hopefully, this helped someone out and if you have and techniques to repair stripped threads in aluminum please feel free to comment them below!

If you’re interested in a seeing a video which demonstrates all of the ways to repair stripped threads in aluminum you can check out the video below!

It’s extremely difficult to remove a seized bolt, too. Looking forward to your article on that one, as well.